Mobile phone QR code

WeChat public account

[Product application]

● Intelligent start/stop control of power transformer cooler

[System interface]

● Passive contact ● Serial interface ● Ethernet interface

[Exterior structure]

● Floor double back plate ● Modular ● Wall mounted

[Cooling form]

● Natural oil circulation air cooling ● Forced oil circulation air cooling ● Forced oil circulation water cooling

[Human-machine interface]

● Display of the current operating state of the equipment ● Display of the current fault alarm ● Setting of system parameters ● Export of the history report

[Control procedure]

● Implement modular programming, which is simple and efficient. ● Preset multiple sets of control logic, to adapt to different control requirements

[Control mode]

● Automatic control: Automatically control the operation of cooling equipment according to the top oil temperature, winding temperature and load signal.

● Remote control Control the operation of the cooling equipment according to the remote command.

● Manual control: Control the operation of the cooling equipment through a change-over switch or a touch screen.

Power management

● The 2-channel power supply is standby for each other, and can be put into and switched automatically or manually, which can provide the fault alarm.

● Separately introduce AC/DC control power supply and power supply redundancy in the cabinet to ensure the reliability of the control system.

[Power management]

● Provide power overvoltage, under-voltage and phase sequence protection.

● Provide overload, short circuit and phase loss protection for fans, oil pumps and other equipment.

[Manufacture and assembly]

● Comply with international, national, industry and corporate standards.

● ISO9000 Quality Management System

● The assembly shall be carried out in strict accordance with the corporate standards.

[Testing and certification]

● The products shall be certified and qualified by a professional power system testing institution.

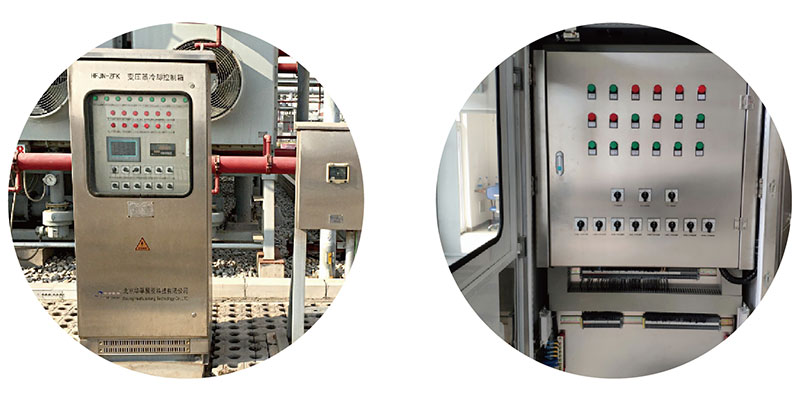

[Cabinet structure]

● The shell and accessories are made of stainless steel (304, 316, etc.).

● Thickness of stainless steel plate: 1.5mm, 2.0mm, 2.5mm.

● The foam seal of cabinet door shall be formed at one time.

● The protection level will not less than IP55.

[Selection of components and elements]

● In terms of the control core, products of Siemens, Schneider, Mitsubishi and other international leading industrial control brands shall be selected.

● In terms of the low-voltage devices, products of Schneider, ABB, Siemens and other international leading brands shall be selected. In terms of the wiring terminals, products of Phoenix and Weidmuller brands shall be used.

● The temperature and humidity regulating device shall be configured.

[Overhaul and maintenance]

● The devices in the cabinet shall be arranged according to function and voltage grade, with clear structure and easy maintenance.

● The control program and firmware version can be upgraded remotely or locally for easy maintenance.

[Ordering instructions]

● The type, group number and rated parameters of the cooler shall be provided. Necessary information such as cabinet installation method and material requirements shall also be provided.